Blog

How 3D Printing is Revolutionizing Manufacturing ?

Future Trends & Industry Insights ▪ 2025-03-12

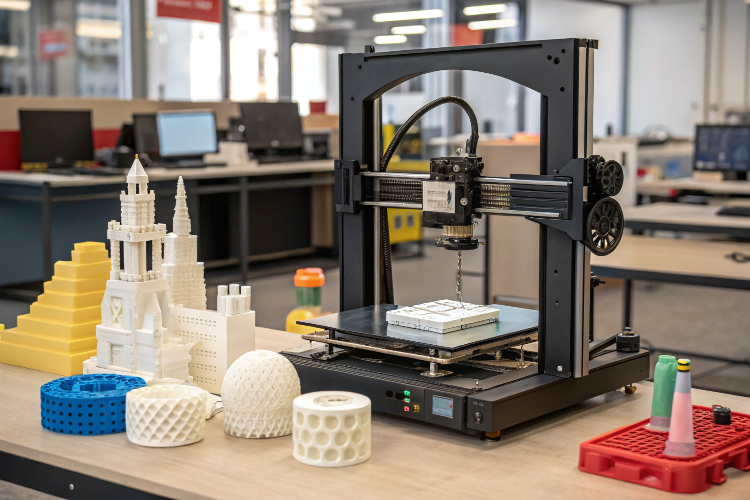

3D printing has emerged as a game-changer in the manufacturing industry, offering unprecedented speed, cost efficiency, and design flexibility. Once considered a niche technology for prototyping, additive manufacturing (AM)—the technical term for 3D printing—has evolved into a mainstream manufacturing process across industries such as aerospace, healthcare, automotive, and consumer goods.

As 3D printing technology advances, businesses are adopting it for mass production, customization, and supply chain optimization, fundamentally transforming the way products are designed, produced, and distributed.

In this guide, we explore how 3D printing is revolutionizing manufacturing, its key benefits, industry applications, and the future impact of this disruptive technology.

1️⃣ What is 3D Printing & How Does It Work?

🚀 3D printing is an additive manufacturing process that builds objects layer by layer from a digital design.

Unlike traditional subtractive manufacturing, which involves cutting material away from a solid block, 3D printing constructs objects from the ground up, reducing waste and enabling complex geometries.

✅ Key 3D Printing Technologies:

✔ Fused Deposition Modeling (FDM) – Uses thermoplastic filaments for rapid prototyping.

✔ Stereolithography (SLA) – Uses liquid resin and UV light for high-precision printing.

✔ Selective Laser Sintering (SLS) – Uses lasers to fuse powdered materials for industrial parts.

✔ Direct Metal Laser Sintering (DMLS) – Used for metal printing in aerospace and healthcare.

💡 Example: Elon Musk’s SpaceX uses metal 3D printing to manufacture rocket engine components, reducing weight and costs.

🔗 Pro Tip: Choosing the right 3D printing method depends on material requirements, precision, and production scale.

2️⃣ How 3D Printing is Revolutionizing Manufacturing

🔹 1. Faster Production & Rapid Prototyping

✔ Traditional manufacturing takes weeks or months to develop prototypes.

✔ 3D printing reduces production time from weeks to hours or days.

✔ Companies can quickly test, modify, and improve designs before mass production.

💡 Example: Ford Motor Company uses 3D printing to create functional prototypes within a few hours, accelerating vehicle development.

🔗 Pro Tip: 3D printing helps businesses reduce R&D costs by iterating designs faster.

🔹 2. Cost-Effective Manufacturing

✔ Traditional manufacturing requires expensive molds and tooling for production.

✔ 3D printing eliminates high setup costs, making small-batch production more affordable.

✔ Reduces material waste by using only the necessary amount of material.

💡 Example: General Electric (GE) reduced the production cost of jet engine fuel nozzles by 30% using metal 3D printing.

🔗 Pro Tip: 3D printing is ideal for low-volume manufacturing and on-demand production.

🔹 3. Customization & Personalization

✔ Traditional manufacturing limits customization due to fixed molds and assembly lines.

✔ 3D printing enables mass customization, allowing businesses to tailor products for individual customers.

✔ Industries like healthcare, fashion, and automotive benefit from personalized 3D-printed solutions.

💡 Example: Adidas’ 3D-printed Futurecraft 4D sneakers provide customized midsoles for optimal performance.

🔗 Pro Tip: 3D printing allows brands to create unique, customer-specific products at scale.

🔹 4. Supply Chain Optimization & On-Demand Manufacturing

✔ Reduces dependency on overseas suppliers and long shipping times.

✔ Businesses can manufacture products locally, cutting down on inventory costs and logistics.

✔ Enables on-demand production, eliminating storage costs for bulk inventory.

💡 Example: The U.S. Navy uses 3D printers on ships to manufacture replacement parts instantly, reducing downtime.

🔗 Pro Tip: Companies can decentralize production with 3D printing, improving supply chain resilience.

🔹 5. Sustainability & Reduced Waste

✔ Traditional manufacturing produces excess waste from cutting and shaping materials.

✔ 3D printing is an eco-friendly process that minimizes material waste.

✔ Some 3D printers use biodegradable and recycled materials to create products.

💡 Example: The construction industry is using 3D-printed houses with sustainable materials, reducing carbon footprints.

🔗 Pro Tip: 3D printing contributes to a circular economy by reducing material waste and energy consumption.

🔹 6. Enhanced Design Flexibility & Complex Geometries

✔ Traditional manufacturing limits design complexity due to tooling constraints.

✔ 3D printing enables intricate designs with lightweight, high-strength structures.

✔ Industries like aerospace and automotive leverage 3D printing to create lightweight, fuel-efficient parts.

💡 Example: Boeing uses 3D-printed titanium components in aircraft, reducing weight and improving fuel efficiency.

🔗 Pro Tip: Engineers can design products that were previously impossible to manufacture with traditional methods.

3️⃣ Industries Benefiting from 3D Printing

🚀 Key industries leveraging 3D printing for innovation:

✅ Aerospace & Defense – Lightweight, high-strength parts for aircraft and rockets.

✅ Automotive – Rapid prototyping and custom car parts.

✅ Healthcare – 3D-printed prosthetics, implants, and medical devices.

✅ Consumer Goods – Custom jewelry, shoes, and eyewear.

✅ Construction – 3D-printed houses and sustainable buildings.

✅ Education & Research – 3D models for interactive learning and scientific experiments.

💡 Example: NASA is developing 3D-printed habitats for Mars exploration.

🔗 Pro Tip: Industries that embrace 3D printing will gain a competitive advantage in cost, innovation, and efficiency.

4️⃣ The Future of 3D Printing in Manufacturing

🚀 Predictions for the future of 3D printing:

✅ Mass Production at Scale – Large-scale 3D printing farms will enable high-volume manufacturing.

✅ Advanced Materials – New materials like biodegradable plastics, carbon fiber composites, and metal alloys will expand 3D printing applications.

✅ AI-Powered 3D Printing – AI-driven optimization will enhance print accuracy and speed.

✅ 3D Printing in Space – NASA and SpaceX are exploring off-world 3D printing for building structures on Mars and the Moon.

✅ Affordable 3D Printing for Everyone – The cost of 3D printers is decreasing, making the technology more accessible to small businesses and consumers.

💡 Example: Elon Musk’s Tesla is integrating 3D printing for advanced electric vehicle manufacturing.

🔗 Pro Tip: Businesses should invest in 3D printing technology now to stay ahead of future advancements.

3D printing is no longer just for prototypes and hobbyists—it is disrupting traditional manufacturing by enabling faster production, customization, cost reduction, and supply chain flexibility. As technology advances, businesses that embrace 3D printing will lead the next industrial revolution.

Key Takeaways:

✅ 3D printing accelerates production, reduces costs, and enables mass customization.

✅ Industries like aerospace, healthcare, and automotive are leading 3D printing adoption.

✅ Sustainable 3D printing materials contribute to a greener, waste-free future.

✅ Future advancements in AI and material science will expand 3D printing capabilities.